Choosing the Best Shingle for Your Metro Detroit Roof: Beyond the “Lifetime” Warranty

If every asphalt shingle is now marketed as a “lifetime” product, how do you genuinely determine which one offers superior protection and longevity for your home or business in Metro Detroit? We understand why consumers are confused. The current blend of aggressive marketing and complex warranty language makes comparing one shingle to another incredibly difficult. Our sincere goal is that by the end of this comprehensive guide, you will be well-informed and able to confidently understand the key factors that define a higher-quality, longer-lasting roofing shingle.

For the purpose of this article, when we use the term “better,” we are specifically referring to longer-lasting performance and durability. These are the 5 key factors to evaluate when selecting your asphalt shingles:

- Shingle Weight (The Critical Factor for Longevity)

This is, without a doubt, the single most important factor. Since asphalt shingles are petroleum-based, they eventually wear out and weather away. A shingle’s water protection comes from the asphalt layer protected by surface granules.- More Granules & Asphalt = Longer Life: The more protective granules there are to shield the asphalt from the sun’s damaging UV rays, and the more asphalt contained within the shingle, the longer the shingle will last compared to a lighter, less-dense alternative.

- The Simple Rule: The heavier the shingle (by weight per 100 sq. ft. of coverage, also known as a “square”), the longer it will take to wear out.

- Consumer Alert: Some manufacturers, like IKO, use a larger shingle size to claim higher weight. Always ask for the weight per square, not the weight of a single bundle.

- The Amount of “Filler” Material

The use of inorganic “filler” has been a contentious topic in the roofing industry for the past 15 years. Manufacturers are increasing the amount of light filler—such as limestone—while simultaneously decreasing the amount of performance-critical asphalt.- Manufacturer Claim: They argue this light filler reduces the shingle’s overall weight, making transport less expensive, without compromising the life expectancy.

- Our Experience: We believe a simple truth remains. More asphalt equals a better, more durable shingle. The reduction in asphalt is primarily a cost-saving measure for manufacturers, driven by the fluctuating cost of petroleum products. We advocate for shingles with a higher concentration of asphalt, not filler.

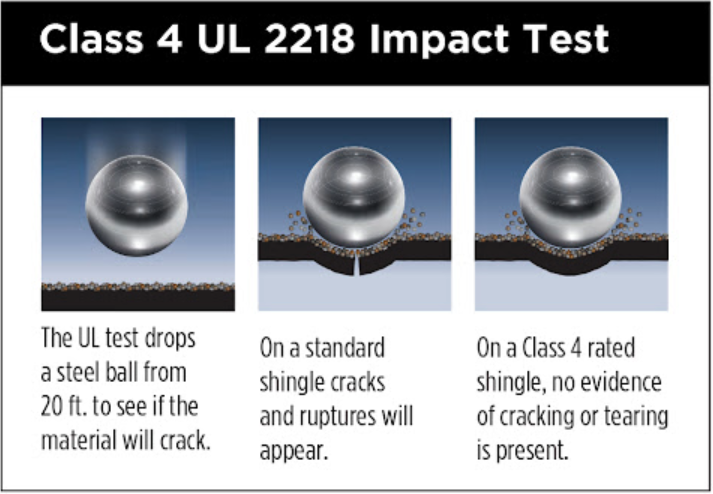

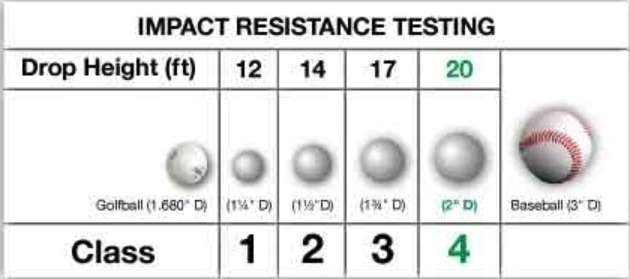

- Impact Resistance Rating (Driven by Insurance Carriers)

This factor is rapidly gaining importance for both homeowners and business owners, largely due to mandates from insurance carriers. Shingles now receive an Impact Class Rating (Class 1-4) based on the size and height of a steel ball bearing they can withstand without damage.- Why It Matters: Insurance companies are increasingly requiring—or providing incentives for—roofs to have a Class 3 or Class 4 impact rating, especially in areas prone to severe weather.

- Superior Resistance: Most shingles achieving a Class 3 or 4 rating incorporate SBS (Styrene-Butadiene-Styrene), a synthetic rubber polymer. SBS infusion gives the shingle increased flexibility, resilience, and superior resistance to hail and storm damage.

- Nail Strip Quality and Reinforcement

The nail strip is critically important for the long-term structural integrity and wind resistance of your roof. Proper installation requires nails to be precisely placed within the designated strip.-

- Defining Quality: A better nail strip is defined by its width and reinforcement.

- Reinforcement: Manufacturers enhance this area through fabric reinforcement (often a synthetic polymer mesh) or by increasing the thickness of the shingle in the nailing zone. This reinforcement is what protects against wind uplift and shingle blow-off if the shingle’s thermal seal strip fails.

- Width: A wider nail strip directly aids the installer, drastically reducing the chance of mistakenly placing a nail above or below the nail line. Nails placed outside the strip compromise wind uplift protection and can potentially void your manufacturer’s wind warranty.

-

- Algaecide Protection (Copper-Infused Granules)

Almost all modern architectural shingles include some level of protection against algae growth, which manifests as unsightly dark streaks or an overall darkening of the roof.-

-

- The Solution: Manufacturers use copper-infused granules to combat this. The copper acts as a natural algaecide.

- The Reality Behind the Names: Many manufacturers use proprietary names, like “Scotch Guard™,” but the reality is that the majority (up to 90%) of these copper-infused granules are sourced from a few suppliers, most notably 3M.

- What to Ask: The real measure of protection is the concentration of copper granules per square foot of the shingle. The more copper-coated granules, the longer and more effective the protection.

- Warranty Check: Ask about the algae warranty and specifically when the proration begins. Many claim a 15-year warranty, but proration can start immediately or within the first 5 years. Look for manufacturers offering full-value algae warranties for up to 15 years, as this indicates a higher ratio of baked-in copper.

-

-

So there you have it—the 5 key factors that truly determine the quality and performance of a roofing shingle. We sincerely hope this detailed breakdown brings clarity to your research process.

We are happy to provide further education and break down the pros and cons of specific shingle lines and manufacturers. If you would like more information or assistance understanding your shingle options, give us a call at 586-566-0308 or schedule a consultation online by CLICKING HERE. We will be happy to send out one of our roofing specialists to meet with you.

Thank you for reading, and we are looking forward to “Hopping To It” for you.

Sincerely,

Bill Burkhardt, Jr.

VP of Marketing – Four Seasons Kanga Roof